Navigating Injection Molding Vendors in China

Well, the major meeting has just concluded. your new product is a go, the timeline is aggressive, and the budget is… well, let’s just say it’s tight.. Then a voice—perhaps your manager or the CFO—drops the line that gives every project manager a shock: “We should look at sourcing this from China.”

You nod, of course. On paper, it’s logical. The cost savings can be huge. But your mind is already racing. You know the rumors, don’t you? Quality failures, endless communication gaps, shipments arriving months late and nothing like the prototype. It feels like walking a thin line between big savings and total project failure.

Here’s the thing, though. Sourcing plastic mold company can be a calculated project. It’s no different from any structured project. And its outcome hinges on the approach you take. It’s not just about the lowest bid but selecting the best partner and overseeing every step. Forget the horror stories. Let’s go through a step-by-step guide to succeed.

Initial Step: Prepare Your Information

Before you mention “supplier” or browse Alibaba, organize your internal data. Truthfully, over fifty percent of offshore sourcing issues originate in an unclear project brief. Don’t assume a remote factory can guess your needs. Sending a vague request is like asking a builder to quote you for “a house.” The responses you get will be all over the map, and none of them will be useful.

Your RFQ should be bulletproof—clear, detailed, and unambiguous. This package is your project’s foundation.

So, what goes in it?

Start with your 3D design files. They’re essential. Provide files in common formats (e.g., STEP, IGS) to prevent import issues. This serves as the definitive part geometry reference.

Yet 3D models don’t cover everything. Include precise 2D engineering drawings. This is where you call out the stuff that a 3D model can’t communicate. Examples include tolerances (e.g., ‘25.00±0.05 mm’), material grade, surface finish requirements, and functional callouts. Any seal surfaces or critical hole sizes must be clearly labeled.

Next up, material. Don’t label it simply “Plastic.” Even “ABS” alone is too vague. Be explicit. Call out SABIC Cycolac MG38 (black), for example. Why? Because plastic grades vary by the thousands. Specifying the exact resin grade ensures you get the strength, flexibility, UV resistance, and color consistency you planned for with plastic mold injection.

They can offer alternatives, but you must provide the initial spec.

Lastly, add your business data. What is your Estimated Annual Usage (EAU)? A supplier needs to know if they’re quoting a tool that will make 1,000 parts in its lifetime or 1,000,000 parts a year. Cavity count, tooling cost, and per-unit pricing depend on volume.

The Great Supplier Hunt

Okay, your RFQ package is a work of art. now, who do you send it to? Online sourcing is global but crowded. It’s easy to find a supplier; it’s hard to find a good one.

Begin on popular marketplaces such as Alibaba or Made-in-China. These are great for casting a wide net and getting a feel for the landscape. But think of them as a starting point, not the finish line. You’ll want to quickly build a list of maybe 10 to 15 companies that look promising.

But don’t stop there. Consider using a sourcing agent. True, they charge a fee. Yet top agents deliver reliable, audited suppliers. They handle local liaison and oversight. For a first-time project, this can be an invaluable safety net. It’s schedule protection.

Another tactic: trade exhibitions. If you can attend, shows such as Chinaplas transform sourcing. Nothing beats a face-to-face conversation. Inspect prototypes, interview engineers, and sense their capabilities. Plus, ask peers for referrals. Ask other project managers in your network. Peer endorsements carry huge weight.

Sorting the Contenders from the Pretenders

After firing off that RFQ to a broad pool, bids begin to arrive. You’ll see ridiculously low offers and steep quotes. Your task is to filter them down to 2–3 credible finalists.

How do you do that? It blends technical checks with intuition.

Step one: audit communication. Are their replies prompt and clear? Is their English good enough for complex technical discussions? The true litmus: are they raising smart queries? Top vendors will critique and inquire. Example: “Should we add draft here for better ejection?” or “Your tolerance may require extended CMM time—okay?” Consider that a big green light. It shows they’re engaged and experienced. Anyone who simply agrees to all specs is a red flag.

Then confirm their machinery specs. Request their machine list. Review examples of parts akin to your design. Don’t pick a micro-molding shop for large components.

Next up: the factory audit. Skipping this is a mistake. Just as you interview hires, audit suppliers. You can either go yourself or, more practically, hire a third-party auditing firm in China to do it for you. They perform a one-day factory inspection. They will verify the company is real, check their quality certifications like ISO 9001, assess the condition of their machinery, and get a general feel for the operation. That small investment can save you thousands.

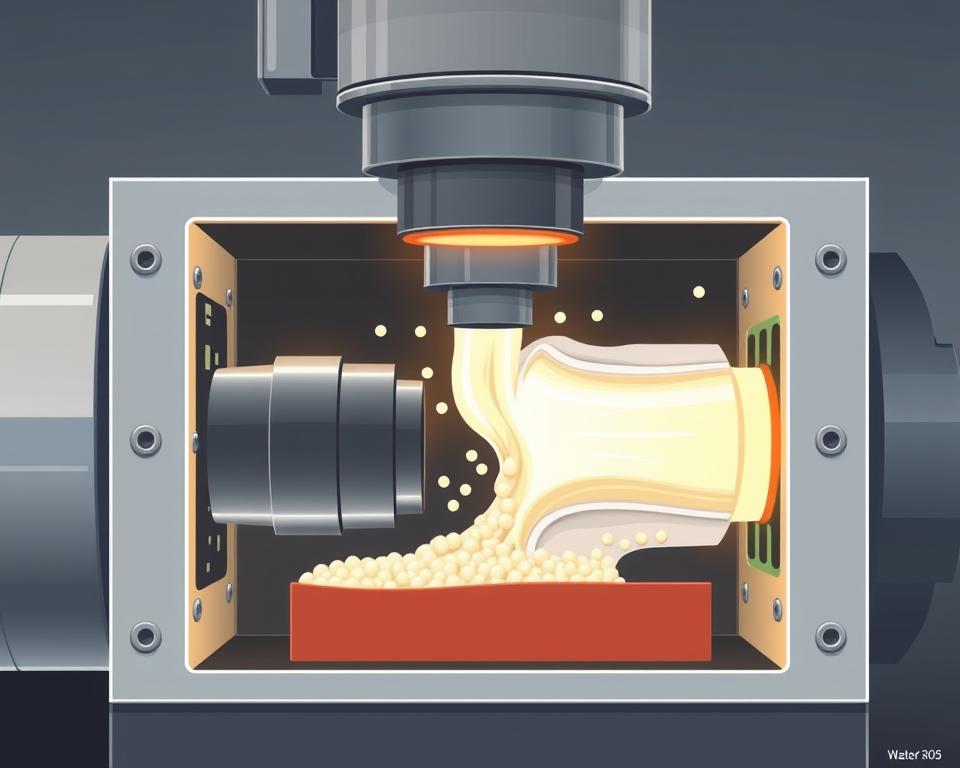

Converting Digital Designs into Molded Parts

You’ve selected your partner. you’ll agree on terms, typically 50% upfront for tooling and 50% upon first-sample approval. Now the process kicks off.

Your supplier’s first deliverable is a DFM analysis. DFM stands for Design for Manufacturability. It’s their professional review of your CAD. They’ll flag thick sections prone to sink, sharp edges that stress, or insufficient draft. A detailed DFM shows expertise. It’s a collaboration. You work with their engineers to refine the design for optimal production.

With DFM sign-off, toolmaking begins. In a few weeks, you’ll see “T1 samples are on the way.” These represent the first trial parts. It’s your first real test.

Be prepared: T1 samples are almost never perfect. This is normal! You’ll find minor defects, off-spec dimensions, or finish issues. You critique, they refine, and T2 plastic mold parts arrive. You may repeat this cycle a few times. The key for you, as the project manager, is to have this iteration loop built into your timeline from the start.

At last, you get the perfect shot. Dimensions, finish, and performance all check out. This is now the benchmark sample. You formally approve it, and this sample is now the standard against which all future mass-produced parts will be judged.

Completing the Sourcing Journey

Getting that golden sample feels like the end, but it isn’t. Next up: mass manufacturing. How do you ensure that the 10,000th part is just as good as the golden sample?

Implement a robust QC plan. Typically, this means a pre-shipment audit. Again, you can hire a third-party service. They’ll sample parts, check dimensions and finish versus your drawings and golden sample, and report. They’ll send you a detailed report with photos and measurements. After your approval, you release the shipment and final funds. This audit shields you from mass defects.

Finally, think about logistics. Clarify your Incoterms. Are you on FOB terms, where they load and you take over? Or is it EXW (Ex Works), where you are responsible for picking it up from their factory door? Your Incoterm selection drives landed expenses.

Overseas sourcing is a marathon. It relies on partnership-building. Treat them like a partner, not just a line item on a spreadsheet. Open dialogue, trust, and rigorous procedure deliver results. No question, it’s demanding. But with this roadmap, you can succeed, achieve savings, and maintain quality. You’re set to succeed.